When it comes to construction, manufacturing, and other industrial applications, serrated flat bars are a versatile and essential component. These bars, distinguished by their serrated edges, offer improved grip and functionality, making them ideal for platforms, stair treads, walkways, and grating applications. Selecting the perfect serrated flat bar for your project requires careful consideration of material, size, and specific application needs. This guide will walk you through the factors to consider to ensure you make the right choice.

What Are Serrated Flat Bars?

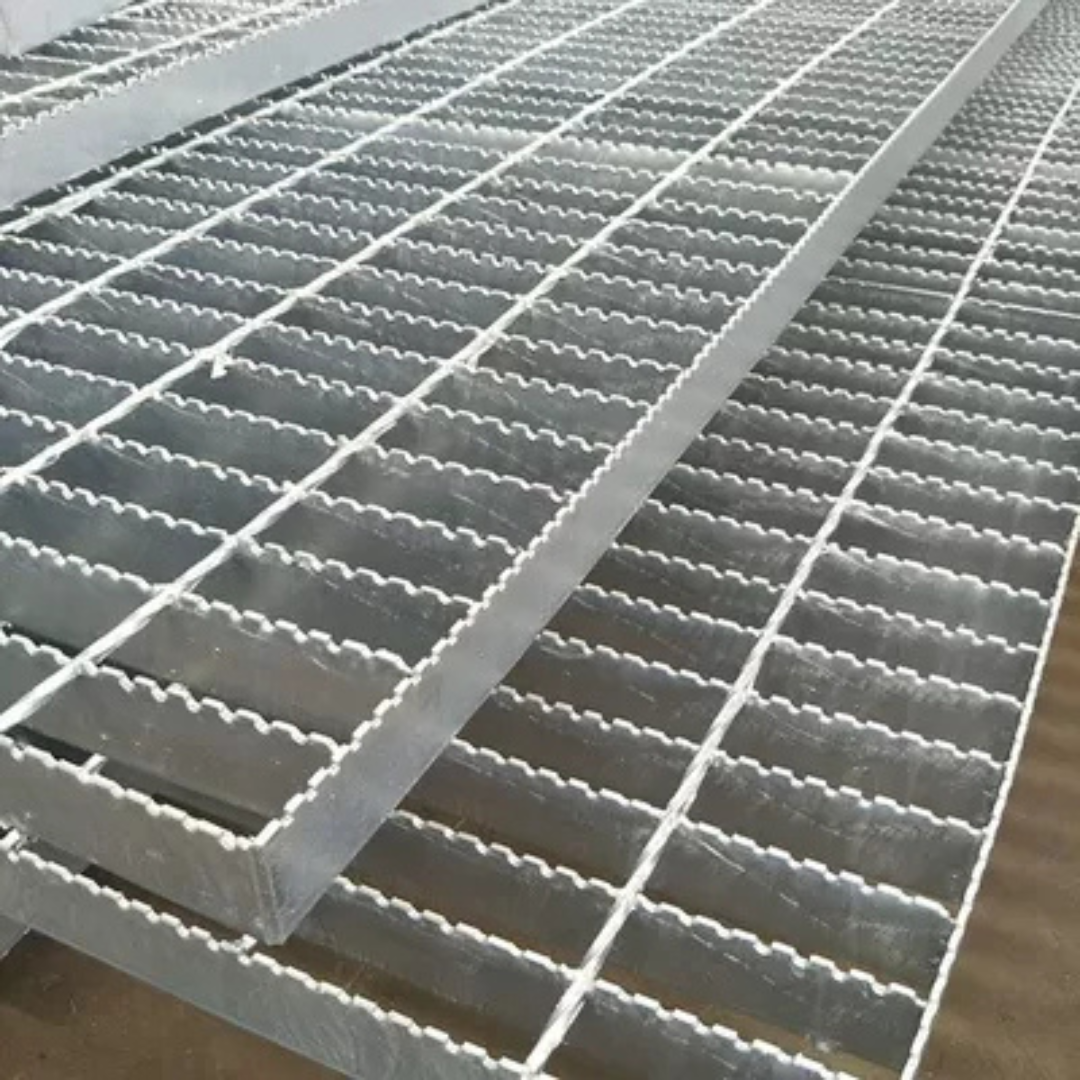

Serrated flat bars are flat pieces of metal with evenly spaced teeth or serrations on one side. The serrations provide enhanced grip and reduce the risk of slips, making them especially useful in environments where safety is a concern. Commonly made from materials like steel, stainless steel, or aluminum, serrated flat bars are a staple in industries ranging from construction to marine engineering.

Why Choose Serrated Flat Bars?

The primary advantage of serrated flat bars is their anti-slip surface. The serrations provide better traction, even in wet or oily conditions, making them suitable for areas with heavy foot traffic or where safety is a priority.

Serrated flat bars are designed to withstand heavy loads and resist wear and tear, making them a durable option for both indoor and outdoor applications.

These bars can be used in a variety of settings, from industrial platforms and stair treads to architectural designs and decorative elements.

Key Factors to Consider When Choosing Serrated Flat Bars

When selecting a serrated flat bar, several factors must be evaluated to ensure the best fit for your project. Let’s break them down:

The material of the serrated flat bar is crucial, as it directly impacts durability, corrosion resistance, and cost. Below are the common materials used and their attributes:

Steel

Stainless Steel

Aluminium

The size of the serrated flat bar determines its load-bearing capacity and suitability for specific applications. Key dimensions to consider include:

Understanding the load your serrated flat bar needs to support is essential to choosing the right one. For heavy-duty applications, opt for bars made from steel or stainless steel with sufficient thickness to handle the load. For lighter applications, aluminium bars may be more cost-effective and easier to handle.

Environmental factors play a significant role in material selection and overall durability. Consider the following:

The intended use of the serrated flat bar will also influence your choice. Common applications include:

Industrial Platforms and Walkways

Stair Treads

Architectural and Decorative Uses

Tips for Ensuring Quality and Cost-Effectiveness

Choosing the right serrated flat bar involves more than just selecting the right material and size. Here are additional tips to ensure quality and cost-effectiveness:

Work with trusted suppliers who provide detailed specifications and quality certifications for their products. Reputable suppliers also offer customization options to fit unique project requirements.

Some materials, like stainless steel, may have a higher upfront cost but require less maintenance over time, making them a more economical choice in the long run.

3. Consider Pre-Finished or Pre-Cut Bars

Pre-finished or pre-cut serrated flat bars can save time and reduce waste, especially for projects with standard dimensions.

Common Mistakes to Avoid

Even with careful planning, mistakes can happen. Here are some common pitfalls to avoid:

Choosing a bar that cannot support the required load can lead to structural failures and safety hazards.

Using the wrong material in a corrosive or wet environment can lead to premature failure and increased replacement costs.

Ensure that the serrated flat bar meets applicable industry standards and safety regulations to avoid compliance issues.

Sustainability Considerations

In today’s environmentally conscious world, sustainability is an important factor in material selection. opt for recyclable materials, such as steel and aluminum, and consider suppliers who follow eco-friendly manufacturing processes.

Conclusion

Selecting the right serrated flat bar for your project is a critical step in ensuring safety, durability, and cost-efficiency. With a comprehensive understanding of material properties, size requirements, load capacity, and environmental factors, you can make a choice that meets your application’s unique needs.

For high-quality serrated flat bars tailored to your project requirements, trust Yaxis Structural Steels, a leading supplier in the industry. With their commitment to quality, precision, and customer satisfaction, Yaxis Structural Steels is your reliable partner for all your structural steel needs.

Contact Yaxis Structural Steels today for expert advice and high-quality serrated flat bars tailored to your project needs. Visit their website at www.yaxissteels.com to explore their offerings. You can also reach them at their address: Plot No. A-80/5, A-80/6, and A-80/7, MIDC Indapur Industrial Area, Loni Deokar, Indapur, Pune – 413132, Maharashtra, India. For immediate assistance, call (+91) 8956025602 or (+91) 8956025601.