The resilience of serrated flat bars is well-known. Because of this, it is commonly utilized as a structural component in the building of things like highways, bridges, and dams. In addition to this, it is put to use in the making of commercial and industrial gratings. YAxis can be your best partner for delivering top-notch serrated flat bars for your project.

The final proportions of the serrated flat can be refined with one flat pass. Electric discharge machining is used to cut the holes in the rolling groove. Before and after the flat reaches the edging pass, its form is carefully managed. However, the serrations are transferred to the flat during the edging pass. Thus serrated flat bars are produced in our factories and then delivered to the customers.

At YAxis Structural Steels, we offer a wide selection of high-quality serrated flat bars that meet stringent industry standards. Our commitment to superior craftsmanship, exceptional customer service, and competitive pricing has made us a trusted partner in the structural steel industry.

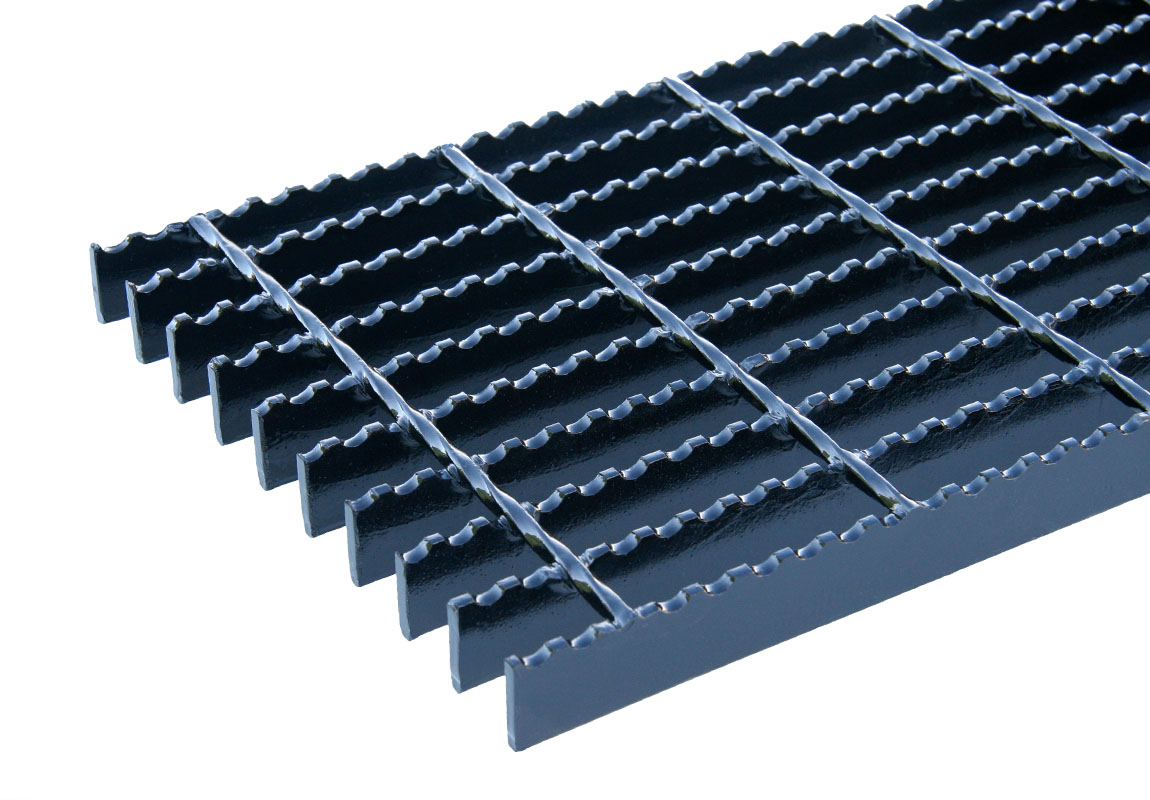

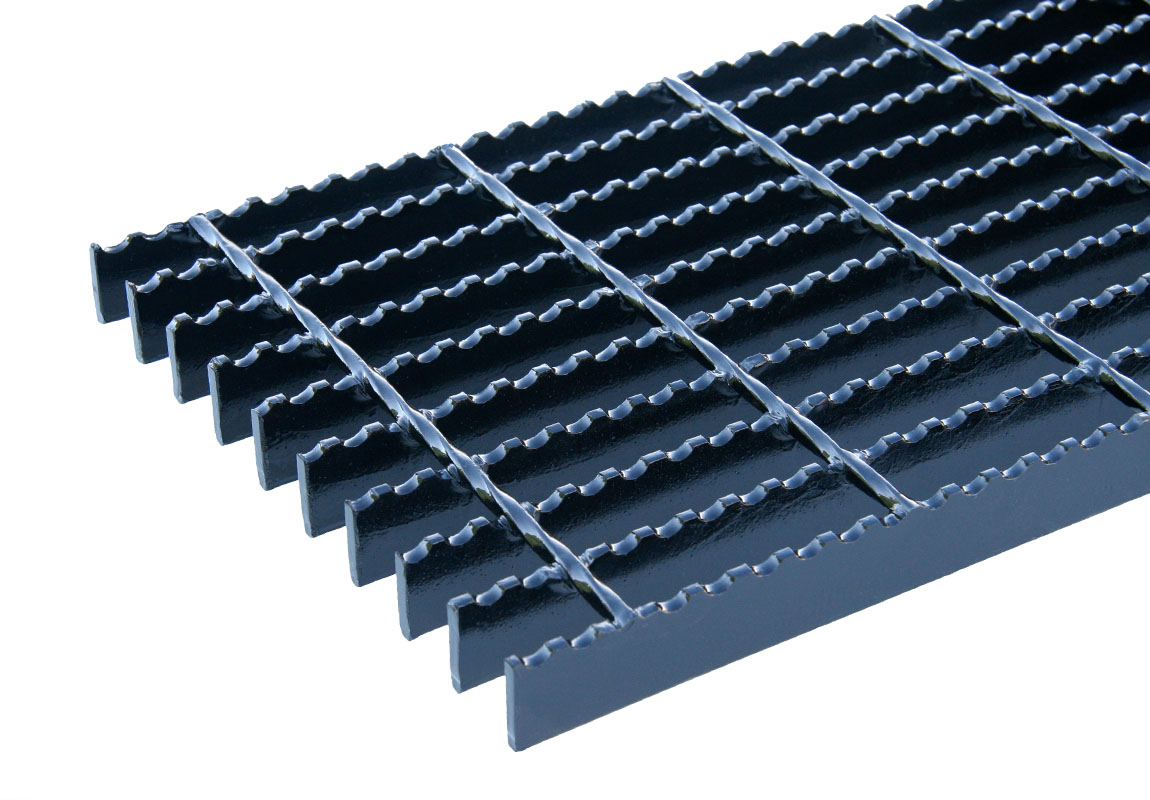

A serrated flat bar is a type of metal bar that features a serrated or jagged surface pattern. It is commonly used in various industries, such as construction, manufacturing, and infrastructure, for applications that require enhanced grip or anti-slip properties.

The serrated surface of the flat bar provides increased traction, making it particularly useful in environments where slip resistance is important, such as walkways, stair treads, ramps, and platforms. The serrations create multiple contact points between the bar and the user’s footwear, reducing the risk of slips, trips, and falls.

Serrated flat bars are available in different materials, such as carbon steel, stainless steel, and aluminum. The choice of material depends on factors such as strength requirements, corrosion resistance, and cost considerations. Carbon steel serrated flat bars are widely used due to their strength and affordability.

The final proportions of the serrated flat can be refined with one flat pass. Electric discharge machining is used to cut the holes in the rolling groove. Before and after the flat reaches the edging pass, its form is carefully managed. However, the serrations are transferred to the flat during the edging pass. Thus serrated flat bars are produced in our factories. Our production unit produces xxxxx tonnes per year.

YAxis supplies serrated flat bars in not only various parts of Maharashtra but also outside of the state boundaries. Clients can inquire about their supplying requirements to understand whether or not we can meet their needs.

The final proportions of the serrated flat can be refined with one flat pass. Electric discharge machining is used to cut the holes in the rolling groove. Before and after the flat reaches the edging pass, its form is carefully managed. However, the serrations are transferred to the flat during the edging pass. Thus serrated flat bars are produced in our factories. Our production unit produces xxxxx tonnes per year.

YAxis supplies serrated flat bars in not only various parts of Maharashtra but also outside of the state boundaries. Clients can inquire about their supplying requirements to understand whether or not we can meet their needs.

YAxis supplies serrated flat bars in not only various parts of Maharashtra but also outside of the state boundaries. Clients can inquire about their supplying requirements to understand whether or not we can meet their needs.

Serrated flat bars are used for various purposes including:

Serrated flat bars are a specialized form of flat bars that offer unique advantages in various applications. At YAxis Structural Steels, we specialize in providing high-quality serrated flat bars that combine enhanced grip, exceptional strength, and versatile functionality for a widerange of construction and industrial projects.

Serrated flat bars are characterized by their serrated or notched surface, which provides excellent grip and slip resistance. The serrations create raised ridges or teeth, enhancing traction and minimizing the risk of slips and falls, even in wet or oily conditions. This makes serrated flat bars an ideal choice for flooring, stair treads, ramps, walkways, and other areas where slip resistance is crucial.

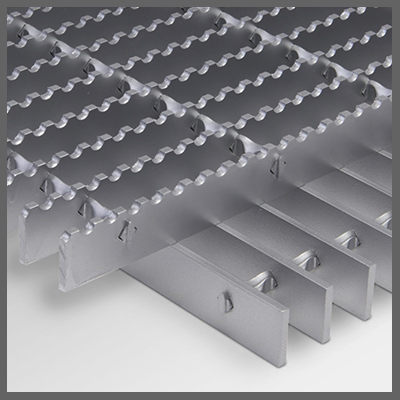

Serrated flat bars have a flat, rectangular profile, making them easy to handle, transport, and install. Their uniform thickness and consistent dimensions allow for seamless integration into various structural elements, such as platforms, gratings, and catwalks.

Our serrated flat bars are constructed from high-quality structural steel or other durable materials, ensuring exceptional strength, longevity, and resistance to corrosion, impact, and environmental factors. This durability makes them suitable for both indoor and outdoor applications.

The serrated surface of flat bars provides enhanced safety by offering excellent traction and slip resistance. This is particularly important in areas with high foot traffic, industrial settings, or locations prone to wet or slippery conditions. The serrations effectively channel away liquids, debris, and other substances, maintaining a secure walking surface and minimizing the risk of accidents.

Serrated flat bars are highly versatile and find application in a wide range of industries. They are commonly used in industrial plants, manufacturing facilities, transportation hubs, construction sites, and commercial buildings. Their durability, grip, and stability make them ideal for creating safe and secure flooring, stair treads, platform gratings, catwalks, and other structural elements

Serrated flat bars offer a cost-effective solution by combining durability and functionality. Their long lifespan, minimal maintenance requirements, and slipresistant properties reduce the need for frequent repairs or replacements, resulting in cost savings over time. Additionally, their ease of installation and compatibility with existing structures contribute to overall project efficiency and cost-effectiveness.

Serrated flat bars not only provide practical benefits but also contribute to the aesthetic appeal of a structure. Their serrated pattern adds visual interest and texture, enhancing the design and creating a modern and contemporary look. This makes serrated flat bars suitable for architectural applications where both functionality and aesthetics are important.

1. Serrated Design: Serrated flat bars are characterized by their serrated or notched surface, which provides excellent grip and slip resistance. The serrations create raised ridges or teeth, enhancing traction and minimizing the risk of slips and falls, even in wet or oily conditions. This makes serrated flat bars an ideal choice for flooring, stair treads, ramps, walkways, and other areas where slip resistance is crucial.

2. Flat Profile: Serrated flat bars have a flat, rectangular profile, making them easy to handle,

transport, and install. Their uniform thickness and consistent dimensions allow for seamless integration into various structural elements, such as platforms, gratings, and catwalks.

3. Durable Materials: Our serrated flat bars are constructed from high-quality structural steel or other durable materials, ensuring exceptional strength, longevity, and resistance to corrosion, impact, and environmental factors. This durability makes them suitable for both indoor and outdoor applications.

1. Enhanced Safety: The serrated surface of flat bars provides enhanced safety by offering excellent traction and slip resistance. This is particularly important in areas with high foot traffic, industrial settings, or locations prone to wet or slippery conditions. The serrations effectively channel away liquids, debris, and other substances, maintaining a secure walking surface and minimizing the risk of accidents.

2. Versatile Applications: Serrated flat bars are highly versatile and find application in a wide range of industries. They are commonly used in industrial plants, manufacturing facilities, transportation hubs, construction sites, and commercial buildings. Their durability, grip, and stability make them ideal for creating safe and secure flooring, stair treads, platform gratings, catwalks, and other structural elements.

3. Cost-Effective Solution: Serrated flat bars offer a cost-effective solution by combining durability and functionality. Their long lifespan, minimal maintenance requirements, and slipresistant properties reduce the need for frequent repairs or replacements, resulting in cost savings over time. Additionally, their ease of installation and compatibility with existing structures contribute to overall project efficiency and cost-effectiveness.

4. Architectural Appeal: Serrated flat bars not only provide practical benefits but also contribute to the aesthetic appeal of a structure. Their serrated pattern adds visual interest and texture, enhancing the design and creating a modern and contemporary look. This makes serrated flat bars suitable for architectural applications where both functionality and aesthetics are important.

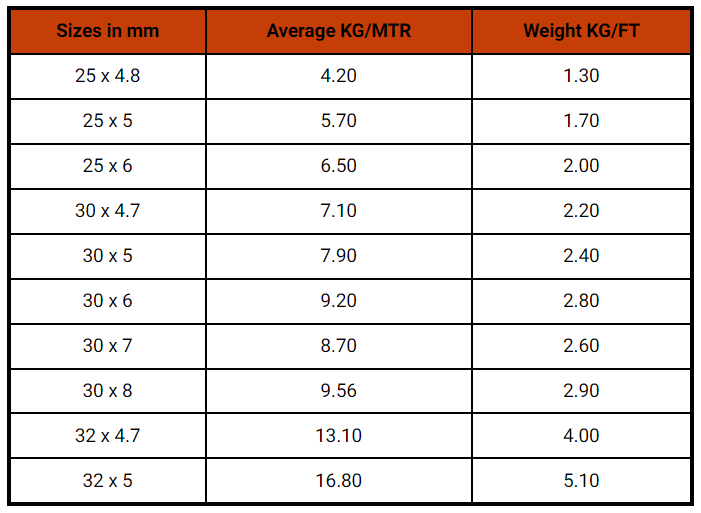

| Sizes in mm | Average KG/MTR | Weight KG/FT |

|---|---|---|

| 25 x 4.8 | 4.20 | 1.30 |

| 25 x 5 | 5.70 | 1.70 |

| 25 x 6 | 6.50 | 2.00 |

| 30 x 4.7 | 7.10 | 2.20 |

| 30 x 5 | 7.90 | 2.40 |

| 30 x 6 | 9.20 | 2.80 |

| 30 x 7 | 8.70 | 2.60 |

| 30 x 8 | 9.56 | 2.90 |

| 32 x 4.7 | 13.10 | 4.00 |

| 32 x 5 | 16.80 | 5.10 |

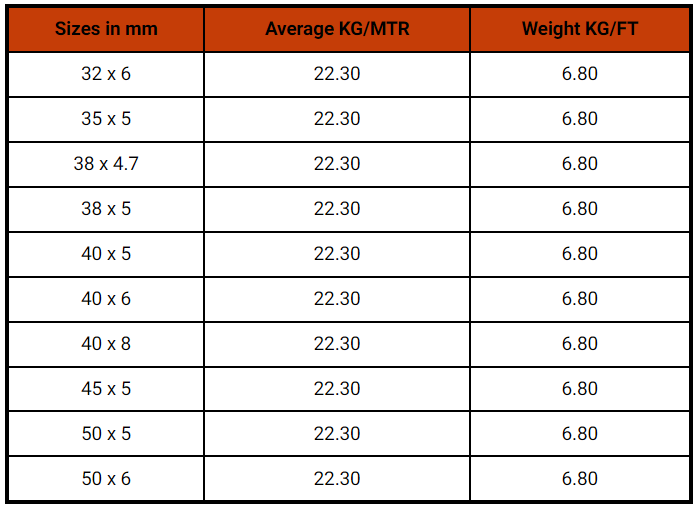

| Sizes in mm | Average KG/MTR | Weight KG/FT |

|---|---|---|

| 32 x 6 | 22.30 | 6.80 |

| 35 x 5 | 22.30 | 6.80 |

| 38 x 4.7 | 22.30 | 6.80 |

| 38 x 5 | 22.30 | 6.80 |

| 40 x 5 | 22.30 | 6.80 |

| 40 x 6 | 22.30 | 6.80 |

| 40 x 8 | 22.30 | 6.80 |

| 45 x 5 | 22.30 | 6.80 |

| 50 x 5 | 22.30 | 6.80 |

| 50 x 6 | 22.30 | 6.80 |

35 x 522.306.8038 x 4.722.306.8038 x 522.306.8040 x 522.306.8040 x 622.306.8040 x 822.306.8045 x 522.306.8050 x 522.306.8050 x 622.306.80

| Sizes in mm | Average KG/MTR | Weight KG/FT |

|---|---|---|

| 25 x 4.8 | 4.20 | 1.30 |

| 25 x 5 | 5.70 | 1.70 |

| 25 x 6 | 6.50 | 2.00 |

| 30 x 4.7 | 7.10 | 2.20 |

| 30 x 5 | 7.90 | 2.40 |

| 30 x 6 | 9.20 | 2.80 |

| 30 x 7 | 8.70 | 2.60 |

| 30 x 8 | 9.56 | 2.90 |

| 32 x 4.7 | 13.10 | 4.00 |

| 32 x 5 | 16.80 | 5.10 |

| 32 x 6 | 22.30 | 6.80 |

copyright@2022 YAxis Structural Steel. Designed & Developed by Websoft Techno