Excerpt: Choosing between square bars and round bars can impact your project’s success. Learn about their differences, strengths, and the ideal use cases for each.

When it comes to construction, manufacturing, or even artistic projects, picking the right material can feel like choosing a needle from a haystack. Two popular choices—square bars and round bars—often make the top of the list. Which one works better for your project? The answer lies in understanding their differences, strengths, and best applications.

In this blog, we’ll break down the differences between square bars and round bars, explore their unique characteristics, and help you make the right call for your next project. So, let’s dive right in.

What Are Square Bars and Round Bars?

Before we compare the two, let’s get a quick overview of what square bars and round bars actually are.

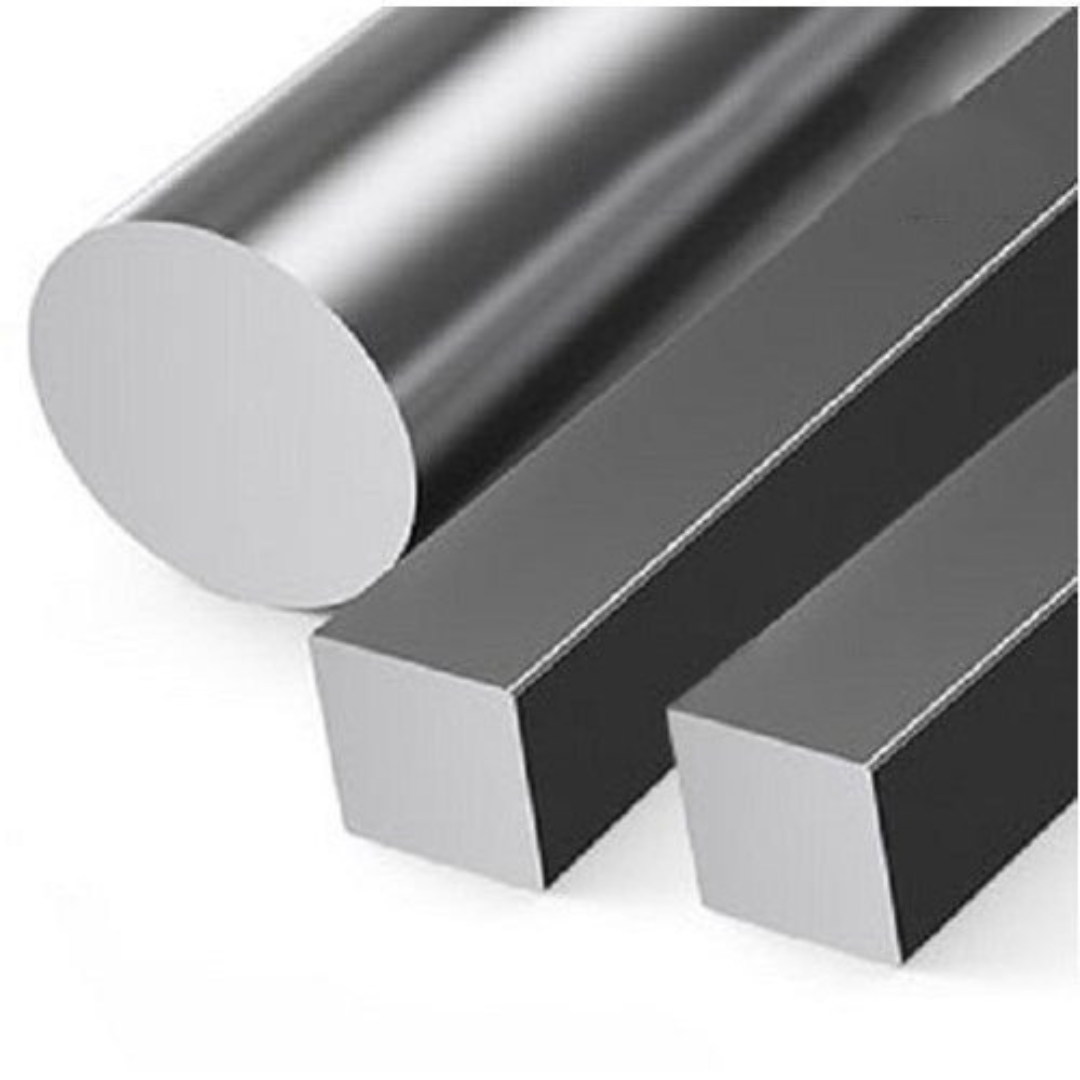

Square bars are metal rods featuring a square-shaped cross-section. They are known for their sharp edges, consistent thickness, and uniform shape. These bars are available in various materials such as steel, aluminium, and brass, making them versatile for several industries.

Round bars, on the other hand, have a cylindrical shape with a smooth, rounded surface. Similar to square bars, they are available in various materials and sizes. Round bars are often used for applications requiring rotation or smooth motion, thanks to their lack of sharp edges.

Key Differences Between Square Bars and Round Bars

Square bars excel in load distribution along their edges, which makes them a strong contender for static structures such as frames and railings. The sharp corners allow for better stress management under compression or direct load.

Round bars, however, are built for motion-based applications. Their circular shape eliminates stress concentrations, making them highly resistant to wear and tear in rotational or tension-based uses like shafts or mechanical parts.

Square bars are rigid and precise. Their flat edges make them easy to weld, cut, and join, which makes them perfect for industrial uses or decorative applications where stability and symmetry are vital.

Round bars, on the other hand, are more adaptable. They can be bent, machined, or shaped easily, making them ideal for projects requiring curves, rotation, or complex designs.

Both square bars and round bars are highly durable, but the way they handle stress differs. Square bars concentrate stress along their edges, which is great for structural stability but limits their effectiveness in motion-based projects.

Round bars distribute stress evenly across their surface, making them better for applications involving dynamic forces, such as gears, axles, or fasteners.

Materials Used in Square Bars and Round Bars

Both types of bars come in a variety of materials, with the choice depending on your project’s specific needs. Here are some commonly used materials:

Real-World Applications: Where Do Square Bars and Round Bars Shine?

Square Bars

Round Bars

Choosing the Right Bar for Your Project

When deciding between square bars and round bars, it’s essential to match their properties to your project’s specific requirements.

Square bars are the ideal choice. They excel in static structures where sharp edges and strong load distribution are crucial.

Round bars are a better fit. Their ability to handle dynamic stress and wear makes them the go-to option for moving parts.

Both square and round bars can be used, depending on the look you want. Square bars give off an industrial, modern vibe, while round bars provide a softer and more polished appearance.

Factors to Consider When Buying Bars

To make an informed decision, you’ll need to consider a few factors:

Practical Advice for Using Square and Round Bars

Whether you are a construction pro or a DIY enthusiast, understanding how these materials behave under different conditions can save you time, money, and effort.

Wrapping

Choosing between square bars and round bars isn’t just a matter of preference—it’s about functionality and design. Square bars are your go-to for static, rigid, and structural applications, while round bars shine in motion-based, flexible, and rotational uses.

By evaluating factors like strength, machinability, and aesthetics, you can select materials that perfectly align with your project goals. For expert guidance and high-quality products, trust YAxis Structural Steels to meet your needs. Contact us today at Plot No. A-80/5, A-80/6, and A-80/7, MIDC Indapur Industrial Area, Loni Deokar, Indapur, Pune – 413132, Maharashtra, India. Call us at (+91) 8956025602 or (+91) 8956025601, or visit our website at https://yaxissteels.com/. Let us help you make the right choice for a sturdy, durable, and visually appealing result.