Excerpt: Serrated grating is durable and slip-resistant for various industrial and commercial applications. Learn how serrated grating works, its top uses, and the major benefits it brings to the table.

Introduction:

Serrated grating might not be a household term, but it plays a critical role in various industries. It’s the kind of thing that keeps workers safe, enhances efficiency, and endures tough conditions. So, let’s dive into what serrated grating is all about, explore where it’s used, and unpack the many advantages that make it a reliable choice.

What is Serrated Grating?

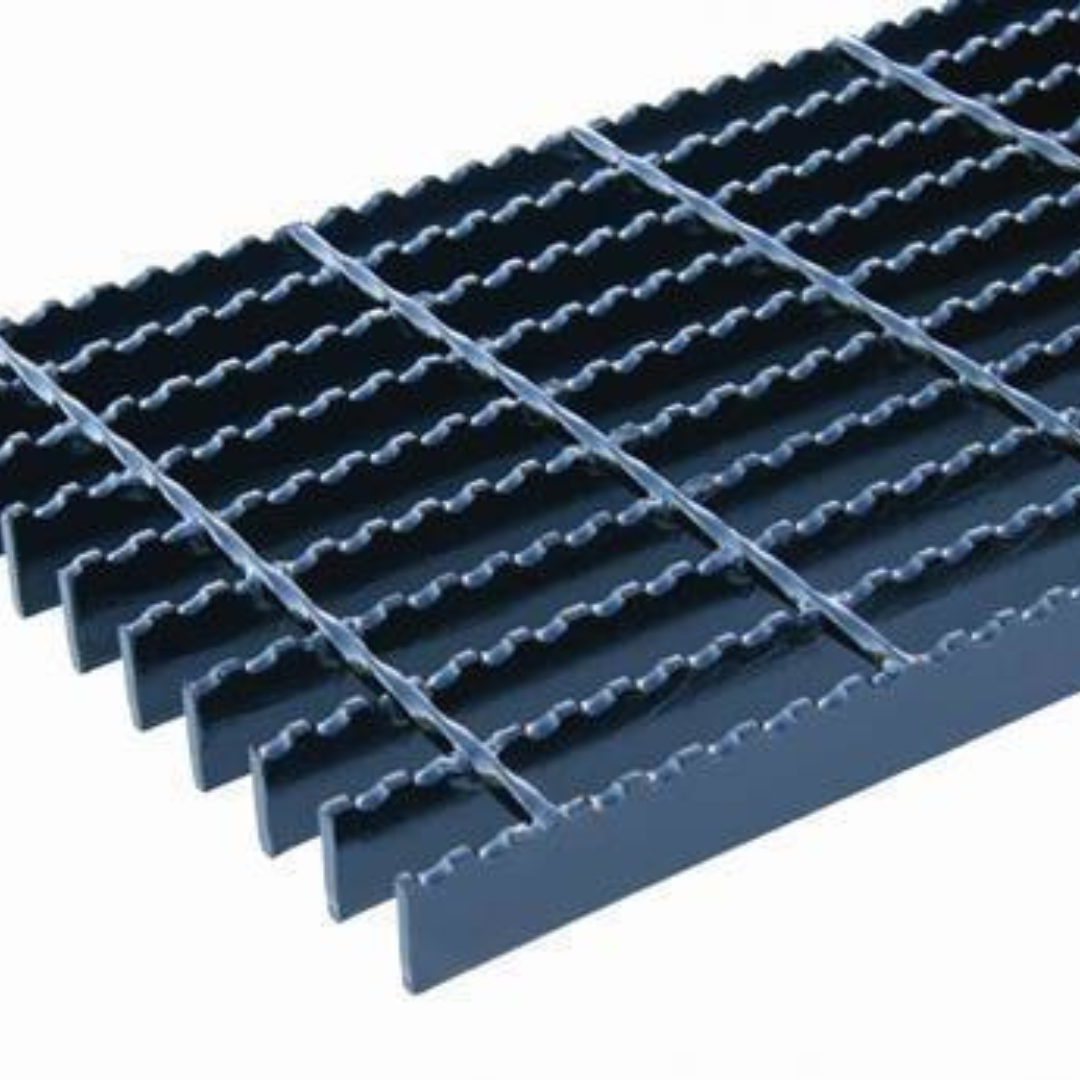

Serrated grating is a type of metal grating featuring a jagged, serrated surface that enhances traction, reducing the risk of slips and falls in wet or hazardous environments. Typically made from galvanized steel for increased durability and corrosion resistance, its robust design makes it ideal for safety-critical applications.

Uses of Serrated Grating

So, where exactly would you come across serrated steel grating? Here’s a summary of some of its most prevalent uses:

1) Industrial Facilities

In heavy-duty industries like manufacturing, mining, and oil and gas, safety is a non-negotiable priority. Serrated steel grating is often installed in walkways, platforms, and stair treads because it provides a secure, non-slip surface even when exposed to liquids, oils, or grease.

2) Construction Sites

Serrated grating is frequently used in construction projects, especially in temporary structures like scaffolding, bridges, or walkways. Its durability and slip resistance make it a go-to solution for worker safety in high-traffic, heavy-use areas.

3) Shipbuilding & Marine Environments

In marine environments where decks, docks, and ramps are constantly exposed to water, having a slip-resistant surface is a must. Serrated grating, especially when galvanized, stands up to salty air and harsh weather conditions without losing its grip-enhancing properties.

4) Chemical & Petrochemical Plants

Because these plants often handle hazardous materials and chemicals, spills are an inevitable part of the job. Serrated grating is used in floorings and walkways to help prevent workers from slipping in these high-risk environments, even when the surface is covered in liquids.

5) Public Infrastructure & Urban Settings

You might not expect it, but serrated grating is even used in urban areas. It can be found in drain covers, footbridges, and pedestrian walkways where non-slip surfaces are essential, especially during rainy or snowy conditions. It’s durable enough to handle heavy foot traffic, vehicles, and even harsh weather conditions.

Advantages of Serrated Grating

Now that we’ve covered where serrated grating is used, let’s take a closer look at its key benefits. Understanding why serrated grating is so popular will help explain its widespread use across industries.

1) Enhanced Slip Resistance

This is the standout feature of serrated grating. The serrated edges provide extra grip, reducing the risk of accidents from slips, especially in environments where water, oil, or other slippery substances are present. This is a major reason it’s used so heavily in industrial, marine, and chemical settings.

2) Durability and Strength

Serrated steel grating is designed to endure tough conditions. Whether it’s heavy loads, constant foot traffic, or exposure to the elements, this type of grating holds up over time. Galvanized serrated grating, in particular, has the added advantage of resisting corrosion, making it ideal for outdoor or marine environments.

3) Low Maintenance

Once installed, serrated grating requires minimal upkeep. It’s built to last, and its open design helps prevent debris buildup. This makes it perfect for environments where dirt, liquids, or other materials could otherwise accumulate and create hazardous conditions.

4) Versatility

Serrated grating comes in a variety of materials (though steel is most common) and sizes, meaning it can be tailored to suit different applications. Whether it’s for large industrial walkways or smaller urban drainage systems, there’s a serrated grating solution that fits the need.

5) Cost-Effectiveness

Considering its long lifespan, durability, and low maintenance requirements, serrated grating is an excellent investment. It minimizes the frequency of replacements or repairs, leading to savings in both time and costs over the long term.

6)Ventilation and Drainage

The open design of serrated grating allows for easy drainage and air circulation. This is crucial in environments like chemical plants, where spillage needs to drain off quickly to avoid creating hazardous situations. It also allows light and air to pass through, which can be important in certain construction settings.

Key Industries that Rely on Serrated Grating

To sum it up, serrated grating is used across a range of industries where safety, durability, and reliability are key concerns. Several industries that depend significantly on serrated steel grating include:

• Manufacturing plants: Heavy machinery and industrial fluids call for strong, slip-resistant surfaces.

• Oil & gas industry: Platforms and walkways in oil rigs require grating that can handle tough environments.

• Marine and shipping: Grating is used on decks and docks where water exposure is a constant.

• Public infrastructure: Walkways, bridges, and drainage systems benefit from serrated grating’s strength and low maintenance needs.

• Chemical processing plants: Safety is essential in environments dealing with hazardous chemicals, where slip-resistant flooring is critical.

Customization Options

A major advantage of serrated grating is its customizability. Manufacturers provide a range of options for material type, bar thickness, and grating size to meet the specific requirements of each project. Galvanized steel is commonly used in industrial settings for its durability, while aluminium is preferred in applications where a lighter weight is necessary. Stainless steel is often selected for environments like food processing that demand high cleanliness and chemical resistance.

Moreover, the spacing between the bars can be tailored to optimize drainage or load capacity, enhancing its functionality. This versatility makes serrated grating an adaptable and smart choice across various industries and environments, ensuring it can effectively address a wide range of safety and performance needs.

Conclusion

Serrated grating is a durable and versatile choice in industrial settings, providing strength and slip resistance for applications like factory platforms and walkways over water. Its long-lasting, low-maintenance nature makes it a smart investment for both industrial and commercial use. Understanding its uses and advantages helps you make informed decisions for your projects.

To learn more about how serrated grating can benefit your projects, visit Yaxis Steels or contact us at (+91) 8956025602 or (+91) 8956025601. You can also visit us at Plot No. A-80/5, A-80/6 and A-80/7, MIDC Indapur Industrial Area, Loni Deokar, Indapur, Pune – 413132, Maharashtra, India. Make an informed decision today.