Discover the many advantages of using MS square bars in metal fabrication. This blog delves into the key benefits of MS square bars and how they can improve your metalworking projects, from easy machining to versatile applications.

Key Benefits of MS Square Bars in Modern Metal Fabrication

When it comes to metal fabrication, using the right materials can make a significant difference in the quality and efficiency of the finished product. MS square bars are one such material that offers several advantages for various fabrication projects. From their exceptional machining capabilities to their versatility in different applications, MS square bars are a preferred choice in many industries. In this blog, we will dive into the key benefits of using MS square bars in metal fabrication, shedding light on how they can improve your projects.

What are MS Square Bars?

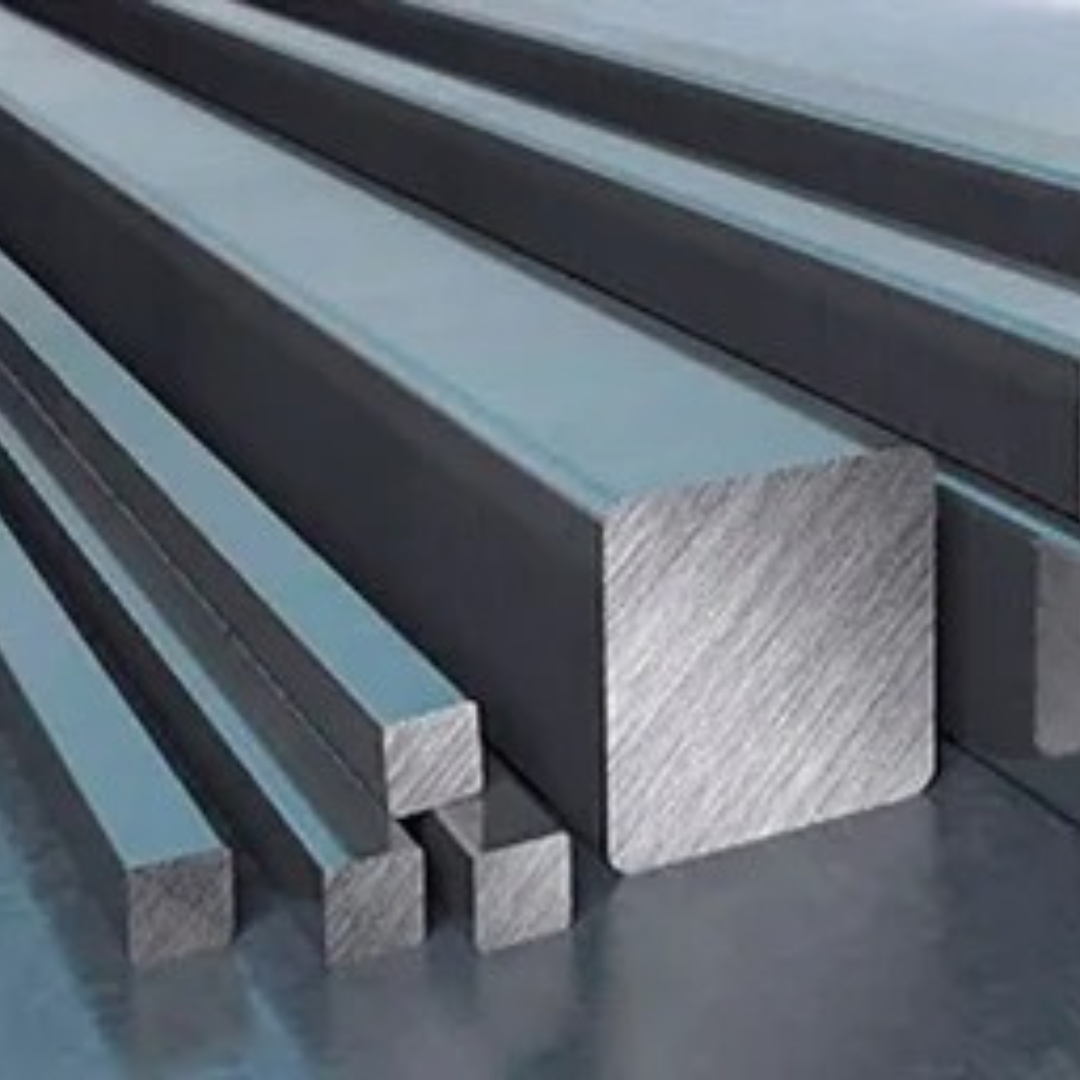

MS, short for mild steel, refers to a type of carbon steel with a low amount of carbon. MS square bars are shaped bars of mild steel that have a square cross-section, making them ideal for various construction, fabrication, and manufacturing applications.

The combination of the material’s composition and its geometric shape makes MS square bars incredibly versatile. They are used in everything from structural components to custom machinery, proving to be an essential material in metalworking.

1. Easy Machining for Precision and Efficiency

One of the top reasons why MS square bars are so popular in metal fabrication is their ease of machining. Because MS square bars are made from mild steel, they are much easier to cut, drill, and shape compared to harder materials. This makes them ideal for projects that require precise dimensions or intricate cuts.

The machining process with MS square bars is smoother, resulting in quicker turnaround times and fewer tool wear-and-tear issues. Whether you are working with CNC machines or hand tools, you will find that the material responds well to various fabrication methods, making it a go-to option for projects requiring fine detail and accuracy.

2. Versatility Across Various Applications

MS square bars offer remarkable versatility in their use. Due to their solid structure and adaptability, they are used in a wide range of applications. From construction frames to structural reinforcements, the material is capable of fulfilling different roles depending on the requirements of the project.

MS square bars can be used in:

Their flexibility allows for use in both large-scale construction and small, precision-based applications, making them indispensable across industries.

3. Welding Suitability

Welding is a critical process in metal fabrication, and MS square bars excel in this area. Mild steel, by nature, is highly compatible with welding techniques. Whether you are using MIG, TIG, or stick welding, MS square bars can be easily welded to other metals or components without worrying about poor joint quality or cracking.

This high welding suitability makes MS square bars a great choice for projects where multiple components need to be joined together, such as in the construction of frames, supports, or custom machinery. The uniform composition of mild steel allows for smooth, clean welds that maintain the integrity of the material, ensuring long-lasting bonds.

4. Cost-Effectiveness for Large Projects

When managing large-scale metal fabrication projects, cost efficiency becomes a major concern. MS square bars, being made from mild steel, are not only affordable compared to other types of metals, but they also offer great value for money. They combine a low initial cost with excellent performance, making them a reliable choice for fabricators looking to stay within budget while still achieving high-quality results.

This cost-effectiveness is especially evident when working on projects requiring large quantities of material. Using MS square bars can help reduce overall expenses while still maintaining the necessary quality and performance standards.

5. Strong Support for Structural Integrity

In any metal fabrication project that involves building or supporting structures, the material’s ability to provide solid, stable support is crucial. MS square bars, with their balanced composition, provide a strong foundation for structural integrity. MS square bars maintain the necessary support for a wide range of applications.

Their well-distributed structure makes them ideal for use in heavy-duty applications, ensuring that they will hold up under both static and dynamic loads, contributing to a solid and reliable structure overall.

6. Available in Various Grades for Specific Needs

MS square bars come in a variety of grades, each offering specific properties tailored to different fabrication requirements. Whether you are working on a project that needs higher machinability, better surface finishes, or enhanced tensile performance, there is an MS square bar grade that can meet those needs.

This flexibility allows fabricators to choose the right material grade for the job, optimizing performance without over-specifying, which helps in reducing costs and improving the project’s overall efficiency.

7. Environmentally Friendly

For modern metalworking and fabrication projects, sustainability has become increasingly important. MS square bars are often more environmentally friendly compared to other metals, as they are made from easily recyclable materials. This makes them a suitable choice for companies looking to minimize their environmental footprint.

Moreover, because mild steel is a widely available material, it requires fewer resources to extract and process, making it an eco-conscious option for large-scale fabrication projects.

Conclusion: Why MS Square Bars Should Be Your Go-To Material

In conclusion, MS square bars offer a range of practical benefits that make them an excellent choice for metal fabrication. From their ease of machining and versatility to their compatibility with welding processes and cost-effectiveness, they stand out as a reliable and efficient option for various industries.

If you are considering your material options for an upcoming metalworking project, MS square bars should certainly be at the top of your list. Their adaptability and excellent performance in different conditions ensure that your fabrication tasks will be completed with precision and reliability.

For high-quality MS square bars and other structural steels, trust Yaxis Structural Steels. Whether you are looking for durable materials for your next project or expert guidance, we are here to help. Visit us at our office located at 607/608, 6th Floor, Clover Hills Plaza, NIBM Road, Kondwa, Pune – 411048, or give us a call at (+91) 8956025602 or (+91) 8956025601. Explore our full range of products and learn more by visiting our website at https://yaxissteels.com/. We look forward to assisting you!