Introduction

Steel grating systems form the backbone of many industrial operations. From walkways in power plants to platforms in factories, steel grating must meet high demands for durability, safety, and performance. But what makes some steel grating systems better than others? The answer lies in the details—specifically, the use of serrated flat bars for steel grating.

These specially designed bars provide enhanced grip, strength, and corrosion resistance, making them indispensable for industrial grating solutions. Let’s explore how serrated flat bars play a crucial role in boosting the durability of steel grating systems, ensuring they last longer and perform better in challenging environments.

What Makes Serrated Flat Bars Unique?

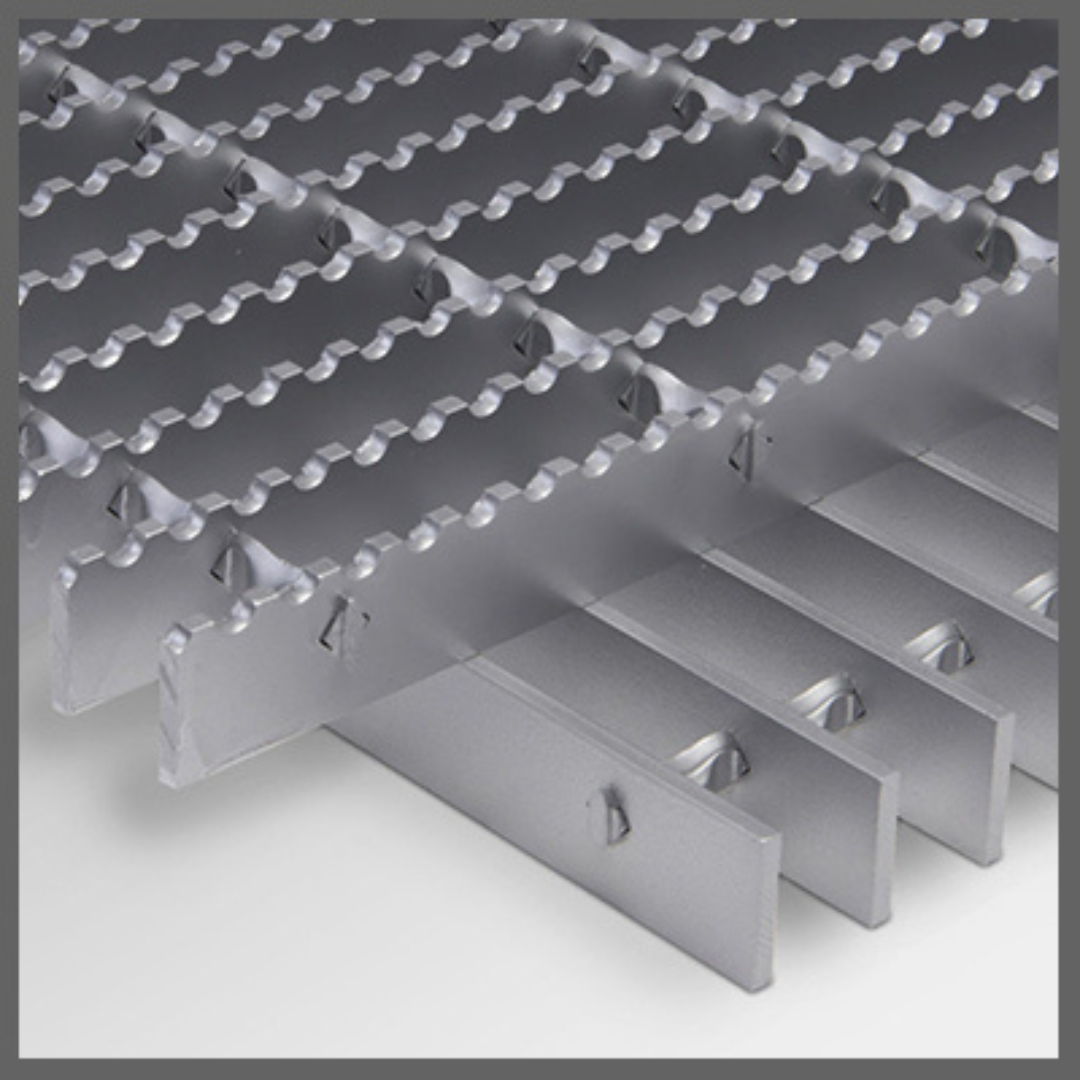

Serrated flat bars are steel bars with notched or ridged edges. Unlike plain bars, these serrations are carefully engineered to provide superior performance in specific applications. Serrated flat bars are a key component of serrated steel grating, where they are welded or assembled into grid-like patterns to create strong, reliable surfaces.

But these ridges aren’t just for show—they directly enhance the safety, longevity, and functionality of steel grating systems.

Benefits of Serrated Flat Bars in Steel Grating Systems

Durability is a critical factor for steel grating systems, especially in industrial environments where they must withstand heavy loads, harsh chemicals, and extreme weather. Serrated flat bars are designed to enhance the overall strength and resilience of the grating.

This makes serrated steel grating a preferred choice for industries requiring high-strength grating systems that can endure constant use and tough conditions.

Slippery surfaces are a common hazard in industrial and commercial settings. Serrated flat bars address this issue by offering excellent slip resistance.

Whether it’s a factory floor, offshore platform, or pedestrian bridge, serrated flat bars ensure a safer environment for workers and equipment.

One of the standout advantages of serrated flat bars is their ability to prolong the lifespan of steel grating systems. By minimizing wear and tear, they keep the grating functional for years, even in high-traffic areas.

This extended lifespan makes serrated steel grating a cost-effective investment for industries that demand long-lasting solutions.

Applications of Serrated Steel Grating

Serrated flat bars enhance the versatility of steel grating, making it suitable for a wide range of industrial and commercial applications. Let’s look at some of the most common uses:

These applications highlight the versatility and reliability of serrated flat bars in creating high-strength grating systems for demanding environments.

How Welding Boosts Durability

The welding process plays a key role in the durability of serrated steel grating systems. Serrated flat bars are often welded to create a robust and unified structure. This not only enhances the load-bearing capacity of the grating but also ensures it can withstand the vibrations and stresses common in industrial settings.

Key Advantages of Welded Grating:

Why Serrated Steel Grating is an Industry Standard

Using serrated flat bars in steel grating systems isn’t just a trend—it’s quickly becoming an industry standard. Here’s why:

The combination of strength, safety, and longevity makes serrated steel grating a go-to solution for businesses worldwide.

How to Choose the Right Serrated Flat Bars

If you are considering serrated flat bars for your steel grating system, here are a few factors to keep in mind:

Consulting with a trusted supplier will help you find the perfect solution for your project.

Key Takeaways

Whether you are designing a walkway, platform, or drainage cover, incorporating serrated flat bars ensures that your grating system performs at its best for years to come.

Conclusion

Serrated flat bars boost steel grating durability, safety, and longevity. Their anti-slip design ensures reliability, making them a cost-effective solution for industrial use.

Looking for Premium Serrated Flat Bars? Contact YAxis Structural Steels today. Visit their website at https://yaxissteels.com/, or head to their address: Plot No. A-80/5, A-80/6, and A-80/7, MIDC Indapur Industrial Area, Loni Deokar, Indapur, Pune – 413132, Maharashtra – India. You can also call them at (+91) 8956025602 / (+91) 8956025601 for more information.