Introduction:

Selecting the appropriate steel beam is essential in construction. W beams and S beams are commonly used, but what sets them apart? In this article, we’ll explore the key differences between W and S beams, including their sizes, applications, and dimensions.

What is the Difference Between W Beam and S Beam?

Steel beams play a vital role in construction, offering the support and stability required to carry loads in buildings, bridges, and various other structures. Not all steel beams are the same. W beams and S beams are two popular choices in structural steel, each with unique features and applications. Understanding the differences between these beams is crucial for selecting the right one for your project.

What are W beams?

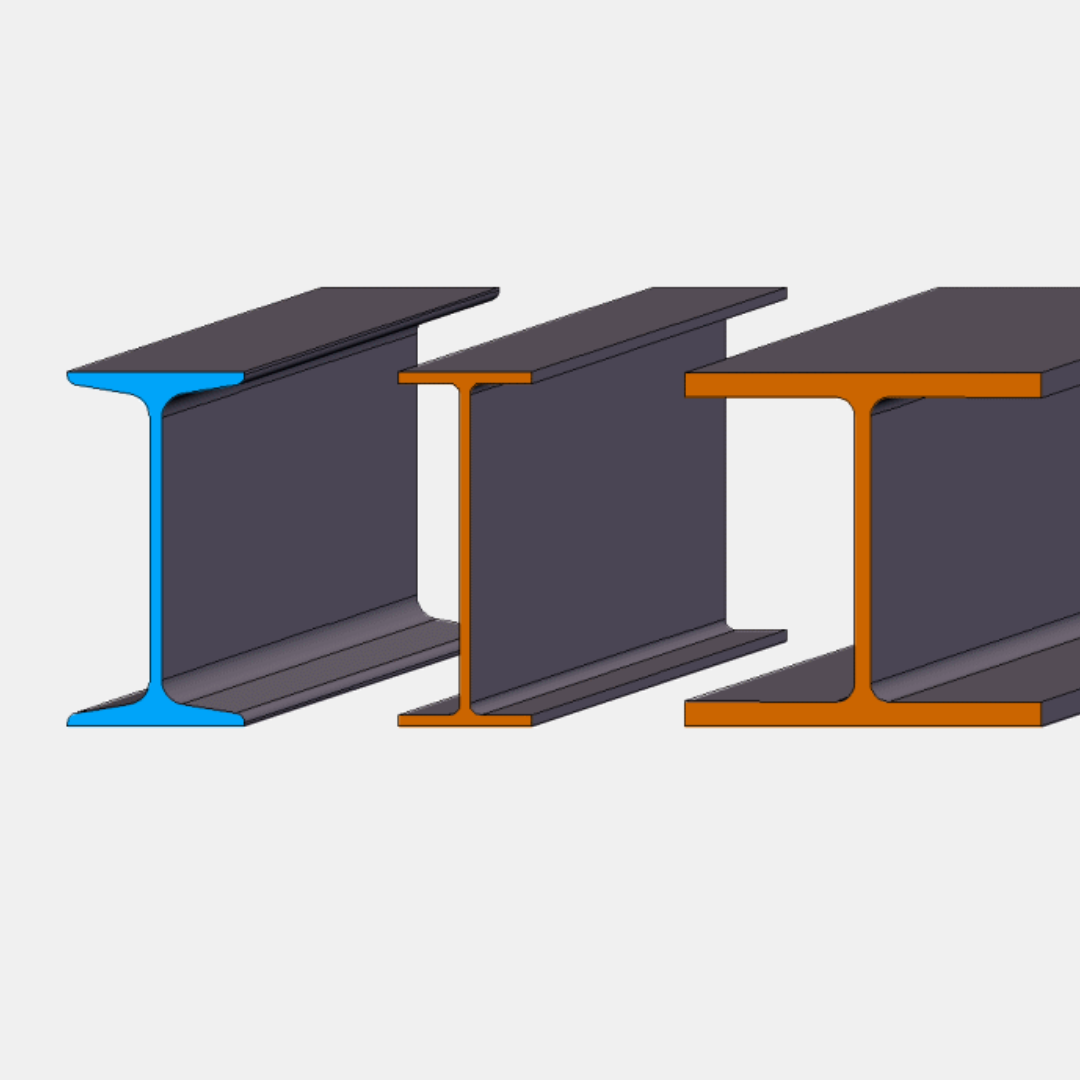

W beams, also known as Wide Flange Beams, are named for their wide and flat flanges (the horizontal sections of the beam). This design feature makes them incredibly efficient in distributing loads over larger areas, which is why they’re often used in buildings with wide spans, bridges, and even in the foundations of large structures.

Key Features of W Beams:

1) Shape: W beams have parallel flanges that are wider than those of S beams. Their web (the vertical section between the flanges) is also typically thinner, but the beam’s overall shape makes it better at distributing loads.

2) Sizes: W beams are available in a broad range of sizes. For example, you may see notations like W8x10, where “W” indicates a Wide Flange beam, “8” refers to the nominal depth of the beam in inches, and “10” represents the weight in pounds per foot.

3) W Beam Dimensions (Metric): In metric terms, these beams can range from around 200 mm to over 900 mm in depth, depending on the application. The weight per meter can vary based on the specific model chosen.

Applications of W Beams:

1) Large Buildings: Due to their strength and ability to carry large loads, W beams are often used in the construction of skyscrapers and other large commercial buildings.

2) Bridges: Their wide flange design helps distribute the load over a broader area, making them ideal for use in bridges.

3) Foundations: W beams provide solid support for foundations, helping to stabilize structures under heavy load conditions.

What are S Beams?

S beams, or Standard Beams, are characterized by their narrow, sloped flanges. These beams have been around for a long time and are still used in various projects today, though not as commonly as W beams. The S beam’s narrower flange makes it ideal for applications that don’t require as much width or load distribution.

Key Features of S Beams:

1) Shape: S beams have flanges that taper as they move away from the web, which gives them their distinctive “I-beam” shape. This tapering can make them slightly less efficient than W beams when it comes to load distribution.

2) Sizes: Like W beams, S beams also come in various sizes, and their notations typically look like S6x12. In this example, the “S” stands for Standard Beam, “6” represents the nominal depth in inches, and “12” is the weight per foot in pounds.

3) S Beam Sizes and Dimensions: S beams are usually available in smaller dimensions compared to W beams. Their depth typically ranges from 3 inches (S3) to 24 inches (S24). Metric equivalents can be anywhere from about 75 mm to 600 mm in depth.

Applications of S Beams:

Residential Construction: Due to their smaller size and load capacity, S beams are often used in residential construction where the loads aren’t as heavy as in commercial buildings.

Smaller Span Structures: S beams can be seen in smaller bridges, walkways, or other constructions where their narrower flanges still offer enough support.

Key Differences Between W Beam and S Beam

Now that we’ve covered the basics, let’s explore their key differences.

1) Flange Design:

W Beams: The flanges are wide and flat, making the beam more stable and able to distribute weight over larger surfaces.

2) S Beams: The flanges are narrower and sloped, which can make them less effective at spreading loads across wide surfaces.

3) Load Capacity:

W Beams: Due to their shape and size, W beams can generally handle more load than S beams, making them ideal for larger structures.

S Beams: These beams are better suited for lighter loads or smaller projects.

4) Beam Sizes:

W Beam Sizes: Available in larger sizes and with a wide range of depths and weights, making them versatile for different applications.

S Beam Sizes: Typically available in smaller dimensions, more suitable for smaller constructions like homes or minor bridges.

5) Usage:

W Beams: Used for skyscrapers, large commercial buildings, bridges, and heavy-duty foundations.

S Beams: More common in smaller projects such as residential homes, small commercial buildings, and walkways.

6) Weight and Cost:

W Beams: Heavier and often more expensive due to their increased size and load capacity.

S Beams: Lighter and more affordable, making them a good option for cost-sensitive, smaller-scale projects.

W Beam vs. S Beam: Which One Should You Choose?

The choice between W beams and S beams depends on your project’s specific needs. If you’re working on a large-scale construction like a skyscraper or bridge, the W beam is likely the better choice due to its superior load-bearing capacity and wide flange design. On the other hand, if you’re building a house or smaller structure, the S beam might be more than adequate and could save you some money in both material costs and installation.

Additionally, W beams are becoming more popular due to their versatility and effectiveness, so they’re now used more frequently in both large and small projects. However, it’s essential to consult with structural engineers who can determine which beam type best suits your project’s needs.

Conclusion

Understanding the difference between W beams and S beams is crucial for selecting the right material for your project. W beams, with their wide flanges and higher load capacity, are ideal for large, heavy-duty structures. On the other hand, S beams are more suitable for smaller projects with lighter load requirements.At Yaxis Structural Steels, we provide a wide range of high-quality structural steel solutions tailored to your project needs. Contact us today to ensure you have the right beams for your build.

Reach us at (+91) 8956025602 or (+91) 8956025601, or visit us at Plot No. A-80/5, A-80/6, and A-80/7, MIDC Indapur Industrial Area, Loni Deokar, Indapur, Pune – 413132 Maharashtra, India. For more information, explore our offerings at https://yaxissteels.com. Let us help you build with strength and precision.