Channel, also known as a C-channel or C-section, is a type of load-bearing structural element commonly used in construction and engineering applications. It is characterized by its “C” shape when viewed in cross-section, with a wide flat top surface, vertical sides (known as flanges), and a narrower flat bottom surface

The selection of a channel depends on factors such as load requirements, span length, material properties, and design considerations specific to the project. It is crucial to consult with a structural engineer or refer to industry standards to ensure the appropriate channel size, material, and connection details for a given application.

Channels are designed to efficiently distribute loads, such as dead loads and live loads, to the supporting elements of a structure. The wide top surface of the channel provides a larger contact area for load distribution, making it suitable for supporting beams, purlins, and other structural components.

Hot-rolled mild steel is the typical material for steel channels. As part of this procedure, a metal strip is passed along a set of rollers, which are also called supports. This causes the strip to be warped until the correct form and shape are achieved. Once the desired shape has been achieved, the rolled material is then cut to size. Our production unit produces xxxxx tonnes per year.

Steel channels that have been manufactured at our plant are either delivered in response to the demand of the customers or in accordance with the contracts that are currently in place. As a result, YAxis is able to supply a wide selection of channels made of mild steel.

Steel channel, along with I-beams and other steel products, is commonly used in many different sectors, such as:

MS channels, also known as Mild Steel channels, are essential components in the construction and engineering industries. At YAxis Structural Steels, we specialize in providing high-quality MS channels that offer versatility, strength, and reliable structural support for a wider range of applications.

MS channels offer reliable structural stability by providing essential support to various construction elements. Whether used as beams, columns, or bracing components, MS channels effectively distribute weight and withstand dynamic forces, ensuring the integrity and safety of the structure.

MS channels find extensive use in a wide range of construction projects, including building frames, industrial platforms, equipment supports, and infrastructure development. Their versatility allows for integration into diverse structural systems, accommodating different design requirements and project specifications.

MS channels are constructed from mild steel, known for its durability, toughness, and resistance to corrosion. This ensures that structures built with MS channels maintain their strength and functionality over time, reducing the need for frequent maintenance or replacements. Their long lifespan makes them a cost-effective choice for longterm projects.

MS channels are highly workable and can be easily cut, welded, drilled, and formed to meet specific project requirements. This flexibility in fabrication allows for customization and adaptability, making MS channels a preferred choice for tailored solutions. Additionally, their standardized dimensions and ease of installation contribute to overall project efficiency.

MS channels are highly versatile and find application in diverse construction projects. With their distinctive “U” shape, MS channels can be used for various purposes, including structural framing, supporting roof and floor systems, creating bracing elements, and forming edges and corners. Their adaptability allows for innovative designs and efficient use of space.

MS channels are renowned for their exceptional strength and load-bearing capacity. The “U” shape provides inherent rigidity and resistance against bending, making MS channels ideal for supporting heavy loads and ensuring structural stability. They contribute to the overall strength and integrity of structures in residential, commercial, and industrial applications.

1. Structural Stability: MS channels offer reliable structural stability by providing essential support to various construction elements. Whether used as beams, columns, or bracing components, MS channels effectively distribute weight and withstand dynamic forces, ensuring the integrity and safety of the structure.

2. Versatile Applications: MS channels find extensive use in a wide range of construction projects, including building frames, industrial platforms, equipment supports, and infrastructure development. Their versatility allows for integration into diverse structural systems, accommodating different design requirements and project specifications.

3. Durability and Longevity: MS channels are constructed from mild steel, known for its durability, toughness, and resistance to corrosion. This ensures that structures built with MS channels maintain their strength and functionality over time, reducing the need for frequent maintenance or replacements. Their long lifespan makes them a cost-effective choice for longterm projects.

4. Ease of Fabrication and Installation: MS channels are highly workable and can be easily cut, welded, drilled, and formed to meet specific project requirements. This flexibility in fabrication allows for customization and adaptability, making MS channels a preferred choice for tailored solutions. Additionally, their standardized dimensions and ease of installation contribute to overall project efficiency.

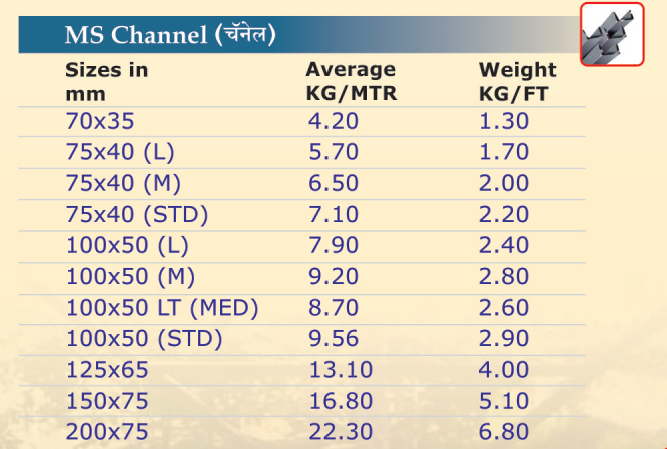

| Sizes in mm | Average KG/MTR | Weight KG/FT |

|---|---|---|

| 70 x 35 | 4.20 | 1.30 |

| 75 x 40(L) | 5.70 | 1.70 |

| 75 x 40(M) | 6.50 | 2.00 |

| 75 x 40(STD) | 7.10 | 2.20 |

| 100 x 50(L) | 7.90 | 2.40 |

| 100 x 50(M) | 9.20 | 2.80 |

| 100 x 50 LT(MED) | 8.70 | 2.60 |

| 100 x 50 (STD) | 9.56 | 2.90 |

| 125 x 65 | 13.10 | 4.00 |

| 150 x 75 | 16.80 | 5.10 |

| 200 x 75 | 22.30 | 6.80 |

This measurement is the entire height of the beam, from the outer surface of the top flange to the outer surface of the bottom flange.

This dimension establishes the width of the flange, from the left to the right of its cross-section. W-beam flanges have the same width.

This is the thickness of the flange from the top surface to the bottom surface. The left and right sides of both flanges should have the same thickness.

The “web” refers to the vertical stem or main body of the beam. This dimension is the thickness across the web from left to right.

copyright@2024 YAxis Structural Steel. Designed & Developed by Websoft Techno

WhatsApp us