Angle is an essential component of structural engineering and construction. They are commonly used to provide support, stability, and reinforcement in various types of structures, such as buildings, bridges, and industrial frameworks. An angle, also known as an L-shaped profile, is formed by two perpendicular legs joined together at a right angle.

Angle is typically made of steel and are available in various sizes, lengths, and thicknesses to suit different structural requirements. They are manufactured through a process called hot rolling, where steel billets or blooms are heated and passed through rolling mills to shape them into the desired L-shaped profile.

The legs of an Angle can have equal or unequal lengths, depending on the application and design specifications. The dimensions of the angle, including leg length, thickness, and overall size, are determined based on the structural loads it needs to bear and the specific engineering requirements of the project.

Angle is an essential component of structural engineering and construction. They are commonly used to provide support, stability, and reinforcement in various types of structures, such as buildings, bridges, and industrial frameworks. An angle, also known as an L-shaped profile, is formed by two perpendicular legs joined together at a right angle.

Angle is typically made of steel and are available in various sizes, lengths, and thicknesses to suit different structural requirements. They are manufactured through a process called hot rolling, where steel billets or blooms are heated and passed through rolling mills to shape them into the desired L-shaped profile.

The legs of an Angle can have equal or unequal lengths, depending on the application and design specifications. The dimensions of the angle, including leg length, thickness, and overall size, are determined based on the structural loads it needs to bear and the specific engineering requirements of the project.

Hot rolling is used to make angles from iron. The steel is heated into a billet and then pressed through rough rollers to bring it to a size near that of an angle. As it passes through the rolls, its thickness is gradually increased.Our production unit produces xxxxx tonnes per year.

Angles made at our facility are supplied as per the demand of the clients or according to the ongoing contracts. Thus a large variety of mild steel angles are supplied by YAxis.

The various uses of steel angles include:

MS Angle, also known as Mild Steel angles, are vital elements in the construction and engineering industries. At YAxis, we specialize in providing high-quality MS angles that offer versatility, strength, and serve as essential structural components for a wide range ofapplications.

MS angles offer reliable structural stability by providing essential support and reinforcement. Whether used as beams, columns, or bracing elements, MS angles effectively distribute weight, resist lateral forces, and contribute to the overall integrity and safety of the structure.

MS angles find extensive use in diverse construction projects, including building frameworks, supports for industrial equipment, reinforcement for concrete structures, and architectural detailing. Their versatility allows for seamless integration into various structural systems, accommodating different design requirements and project specifications.

MS angles are constructed from high-quality mild steel, known for its durability and resistance to corrosion. This ensures that structures built with MS angles maintain their strength and functionality over time, reducing the need for frequent maintenance or replacements. Their long lifespan makes them a cost-effective choice for longterm projects.

MS angles are highly workable and can be easily cut, welded, drilled, and formed to meet specific project requirements. This flexibility in fabrication allows for customization and adaptability, making MS angles suitable for tailored solutions. Additionally, their standardized dimensions and ease of installation contribute to overall project efficiency.

MS angles are renowned for their versatility and can be used in various construction projects. With their “L” shape, MS angles are suitable for a multitude of applications, including framework construction, bracing, supports, corner reinforcement, and creating edges. Their adaptability allows for efficient use of space and facilitates innovative designs.

MS angles possess excellent strength and structural integrity, making them a reliable choice for load-bearing applications. The “L” shape design provides exceptional resistance against bending and ensures stability in different structural configurations. MS angles play a critical role in enhancing the strength and overall stability of structures.

1. Structural Stability: MS angles offer reliable structural stability by providing essential support and reinforcement. Whether used as beams, columns, or bracing elements, MS angles effectively distribute weight, resist lateral forces, and contribute to the overall integrity and safety of the structure.

2. Versatile Applications: MS angles find extensive use in diverse construction projects, including building frameworks, supports for industrial equipment, reinforcement for concrete structures, and architectural detailing. Their versatility allows for seamless integration into various structural systems, accommodating different design requirements and project specifications.

3. Durability and Longevity: MS angles are constructed from high-quality mild steel, known for its durability and resistance to corrosion. This ensures that structures built with MS angles maintain their strength and functionality over time, reducing the need for frequent maintenance or replacements. Their long lifespan makes them a cost-effective choice for longterm projects.

4. Ease of Fabrication and Installation: MS angles are highly workable and can be easily cut, welded, drilled, and formed to meet specific project requirements. This flexibility in fabrication allows for customization and adaptability, making MS angles suitable for tailored solutions. Additionally, their standardized dimensions and ease of installation contribute to overall project efficiency

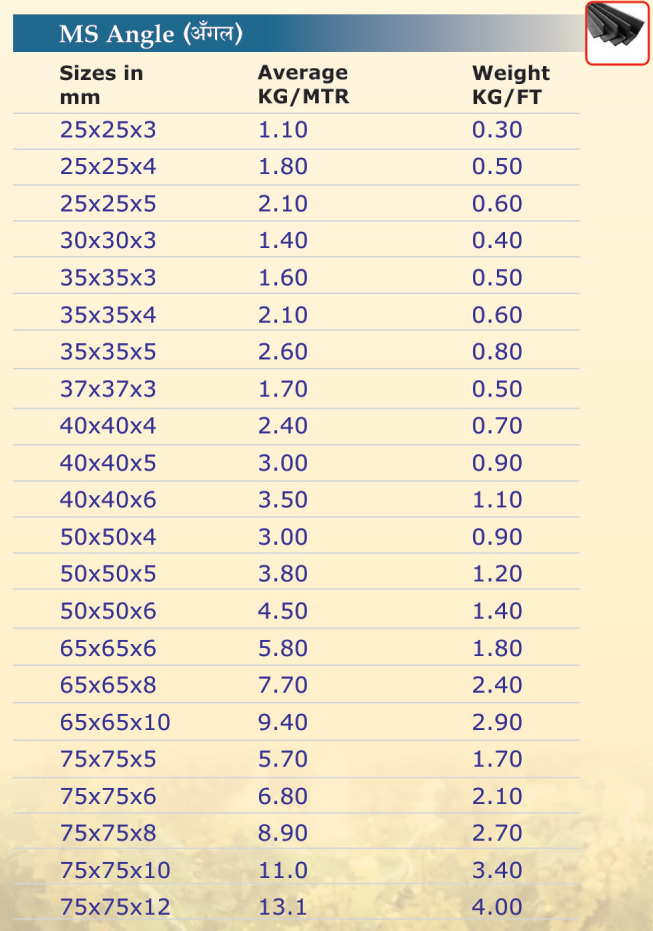

| Sizes in mm | Average KG/MTR | Weight KG/FT |

|---|---|---|

| 25 x 25 x 3 | 1.10 | 0.30 |

| 25 x 25 x 4 | 1.80 | 0.50 |

| 25 x 25 x 5 | 2.10 | 0.60 |

| 30 x 30 x 3 | 1.40 | 0.40 |

| 35 x 35 x 3 | 1.60 | 0.50 |

| 35 x 35 x 4 | 2.10 | 0.60 |

| 35 x 35 x 5 | 2.60 | 0.80 |

| 37 x 37 x 3 | 1.70 | 0.50 |

| 40 x 40 x 4 | 2.40 | 0.70 |

| 40 x 40 x 5 | 3.00 | 0.90 |

| 40 x 40 x 6 | 3:50 | 1.10 |

| Sizes in mm | Average KG/MTR | Weight KG/FT |

|---|---|---|

| 50 x 50 x 4 | 3.00 | 0.90 |

| 50 x 50 x 5 | 3.80 | 1.20 |

| 50 x 50 x 6 | 4.50 | 1.40 |

| 65 x 65 x 6 | 5.80 | 1.80 |

| 65 x 65 x 8 | 7.70 | 2.40 |

| 65 x 65 x 10 | 9.40 | 2.90 |

| 75 x 75 x 5 | 5.70 | 1.70 |

| 75 x 75 x 6 | 6.80 | 2.10 |

| 75 x 75 x 8 | 8.90 | 2.70 |

| 75 x 75 x 10 | 11.0 | 3.40 |

| 75 x 75 x 12 | 13.1 | 4.00 |

copyright@2024 YAxis Structural Steel. Designed & Developed by Websoft Techno

WhatsApp us