Choosing between hot-dipped galvanized and stainless steel serrated flat bars can be tricky. This guide breaks down their durability, corrosion resistance, and cost-effectiveness to help you make the best decision.

Introduction: The Ultimate Showdown

Both options offer strength, corrosion resistance, and longevity, but their differences can make or break your project. The right choice depends on factors like budget, environmental conditions, and maintenance requirements.

In this guide, we will compare galvanized vs. stainless steel serrated flat bars, covering their pros, cons, and best-use scenarios so you can make a confident, informed decision.

What Are Serrated Flat Bars?

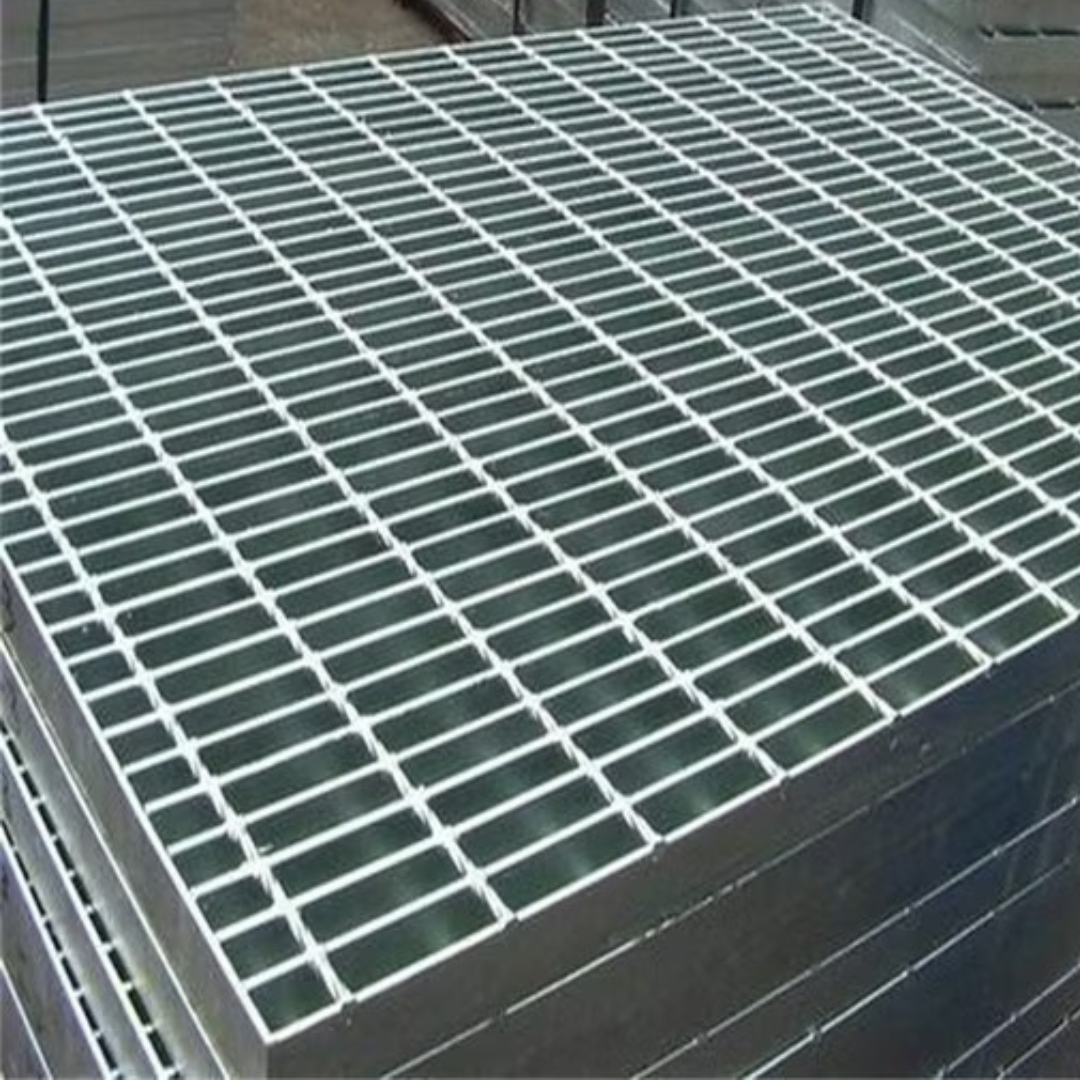

Serrated flat bars are steel bars with notched edges, specifically designed to provide enhanced grip and slip resistance. Unlike smooth flat bars, the serrated edges create extra friction, making them an excellent choice for applications where safety, drainage, and durability are key concerns.

These bars are commonly used in industrial and commercial settings, where floors and walkways are exposed to moisture, oils, or other potentially slippery substances. Their textured surface helps reduce the risk of slips and falls, making them a preferred option in environments where worker safety is a priority.

Common Applications of Serrated Flat Bars

The two most popular types are hot-dipped galvanized and stainless steel, each with its advantages.

Hot-Dipped Galvanized Serrated Flat Bars

What Is Hot-Dipped Galvanization?

Hot-dipped galvanization is a process where carbon steel is coated with a layer of zinc, forming a protective barrier against rust and corrosion.

Advantages of Hot-Dipped Galvanized Flat Bars

Disadvantages of Hot-Dipped Galvanized Flat Bars

Best Applications for Galvanized Serrated Flat Bars

Stainless Steel Serrated Flat Bars

What Makes Stainless Steel Different?

Stainless steel contains chromium (at least 10.5%), which forms a passive oxide layer, preventing rust and corrosion without additional coatings.

Advantages of Stainless Steel Flat Bars

Disadvantages of Stainless Steel Flat Bars

Best Applications for Stainless Steel Serrated Flat Bars

Key Comparison: Hot-Dipped Galvanized vs. Stainless Steel

Corrosion Resistance

Hot-dipped galvanized flat bars provide good corrosion resistance, but the zinc coating can wear off over time. Stainless steel, on the other hand, offers superior rust resistance due to its chromium content, making it a better choice for extreme conditions.

Cost Considerations

If you are on a budget, galvanized steel is the more affordable option. Stainless steel is significantly more expensive, but its long lifespan and minimal maintenance costs can justify the higher initial investment.

Durability and Lifespan

Galvanized steel can last 20 to 50 years, depending on environmental exposure. Stainless steel, however, can last 50+ years with little to no maintenance, making it a long-term solution for demanding applications.

Maintenance Requirements

Galvanized steel requires occasional inspections and potential recoating if the zinc layer deteriorates. Stainless steel is virtually maintenance-free, as it does not require protective coatings to prevent rust.

Strength and Structural Integrity

Both materials are strong, but stainless steel has a higher tensile strength and is more resistant to impact and wear. This makes it ideal for applications where high durability is required.

Visual Appeal

Stainless steel has a sleek, polished appearance, making it suitable for architectural and decorative applications. Galvanized steel has a duller, industrial finish, which is better suited for practical applications rather than Visual appeals.

Which One Should You Choose?

Choose Hot-Dipped Galvanized Serrated Flat Bars

When considering cost-effectiveness, durability, and corrosion resistance for general construction or outdoor use, hot-dipped galvanized serrated flat bars emerge as the superior choice. They provide a budget-friendly solution while offering reliable protection against rust, making them ideal for structural, industrial, and exterior applications.

While stainless steel excels in visual appeal and extreme corrosion resistance, its higher cost makes it less practical for many common uses. Unless your project demands marine-grade durability or architectural appeal, galvanized steel provides the best balance of affordability and performance, making it the smarter investment for most applications.

Final Thoughts – Make the Right Choice Today!

Now that you understand the differences between galvanized vs. stainless steel serrated flat bars, it’s time to make an informed decision.

For high-quality serrated flat bars at competitive prices and expert guidance on the best option for your project, contact YAxis Structural Steels today. Visit our office at 607/608, 6th Floor, Clover Hills Plaza, NIBM Road, Kondwa, Pune – 411048, or call us at (+91) 8956025602 | (+91) 8956025601. For more details, visit our website at https://yaxissteels.com/. Let our experts help you find the perfect serrated flat bars for your needs.